Matt's Story

- 29 Apr 2022

How we Helped Matt’s Colorado Woes

HPD feel extremely happy and proud to end the nine-month ordeal of a country Far North Queenslander who lost his livelihood due to a work vehicle becoming so unreliable, he couldn’t work.

Matt bought an RC Colorado dual cab ute and soon after sourced some performance upgrades, including a Steinbauer Power Module, LPG injection and a HPD top mount intercooler kit.

The ordeal started after a mechanic incorrectly installed the HPD intercooler kit. As soon as Matt drove away from the workshop, he was gutted to feel he had less power than before.

Something didn’t smell right…

Matt and his mechanic didn’t realise the intercooler was losing boost as the smell of gas suggested there was a problem with the LPG system.

After a trip to the LPG specialist to repair a leaky line to the turbo, the ‘Collie’ ran reasonably well for a short while, albeit raucously. Matt experienced excessive noise and vibrations resonating through the cabin due to the intercooler rubbing against the bonnet. The reason? The intercooler was not sitting flat; one side was positioned too high and rubbed against the underside of the bonnet. This cacophony turned out to be the least of Matt’s problems.

The Colorado would suffer power loss, and on most trips would become virtually undriveable due to regularly running in the dreaded limp mode. Despite several trips back to the mechanic who installed the intercooler to try and make things right and running it on the dyno again to check for issues & power output, Matt’s Colorado conflict continued. It became too much of an inconvenience to drive it any considerable distance.

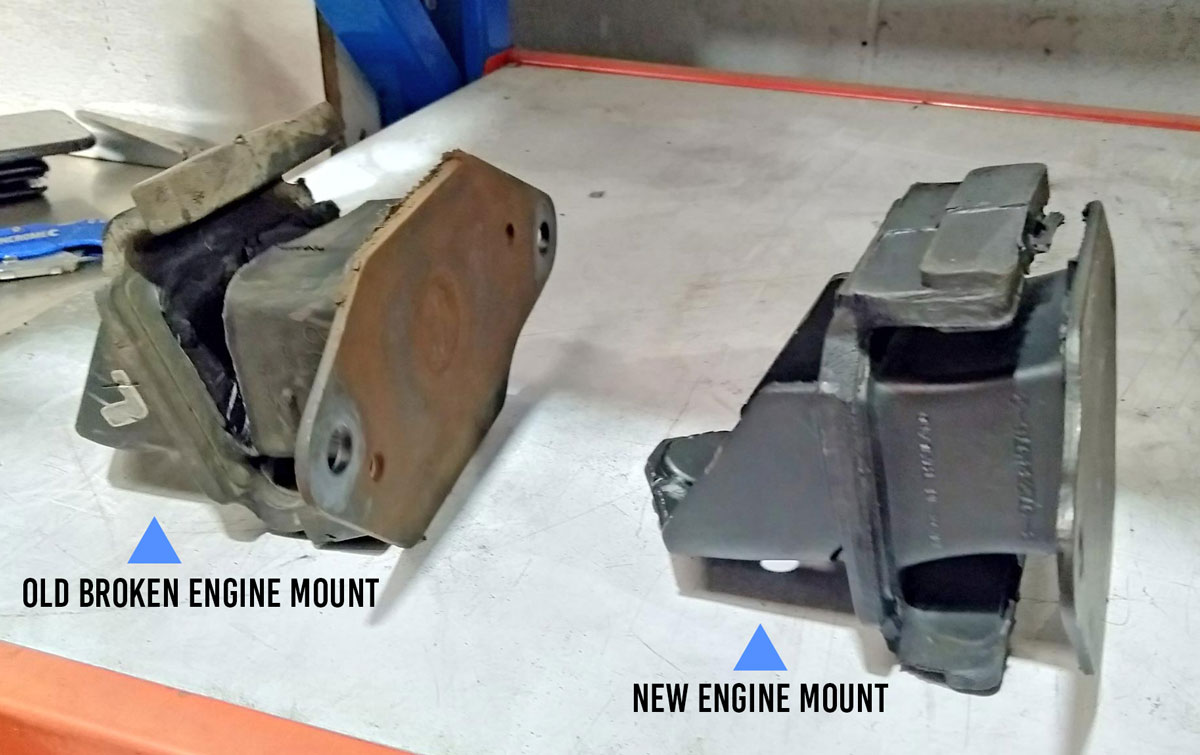

One of the two broken engine mounts; one of the reasons for the unlevel intercooler assembly

Grim discoveries

Matt has performed plenty of work on his cars in the past, so naturally he had a crack at figuring out what was wrong. He took the car to another workshop where they discovered that the mechanic who fitted the intercooler, damaged part of the wiring loom connecting the throttle body on the intake. He also broke a clip on the airbox lid, which no longer sealed correctly, letting dust and other foreign particles into the intake system, destroying the MAF sensor. This meant the tune he paid for was performed with incorrect MAF sensor data.

After all the expense of replacing parts, the Colorado’s limp mode madness continued. The list of bits bought not only included the broken section of wiring loom, throttle body and a MAF sensor (or two), but a water pump and harmonic balancer as well (unrelated to intercooler issues.)

This nightmare had now dragged on for nine months. By now, Matt had spent a considerable amount of his money on this work vehicle. A business investment to enable him to earn a living, instead bled him financially dry. The dual cab was so unreliable that Matt had no means of earning any significant income, let alone enjoy his frequent fishing and camping trips.

Throughout this torment, Matt and the various mechanics along the way were in contact with us. We were perplexed. With hundreds of RC Colorado top mount kits sold, we’ve never encountered these problems before. Without the ability to cast our hands over the Holden, photos and conversations weren’t enough for us to find the problem. Then we finally got our hands on it.

Braving the odds

Matt had no choice but to brave the odds and drive to Adelaide to visit his father who had suddenly fallen ill. This unfortunate event gave HPD the opportunity to provide Matt with much-needed hands-on support just two days before the Easter long weekend.

During the difficult, anxiety-filled journey, towing a huge camper trailer, he had to stop for a while in Southwest Victoria, where the workshops he dealt with couldn’t make the vehicle run properly either.

Finally arriving at HPD in Adelaide, it didn’t take long for us to determine that the main issue was loss of boost from the intercooler. We just had to figure out where it was leaking from. Worryingly, with the intercooler mounted, there was a lot of tension on the LHS mounting points on the mounting bracket provided, and we found a gap of around 10-15mm with the mounting bolts removed. This gap was what was letting the intercooler contact the bonnet. The severely kinked silicone hose from the turbo to the intercooler would not have provided any performance advantage either.

After a tear-down and thorough examination, we were satisfied that all the parts we manufactured and provided were correct – the intercooler was checked against the fabrication jig, and the intercooler was not faulty. Aiden, who built the intercooler kit confidently revealed, “I never had a doubt!”

The horrible truth

So, why couldn’t the intercooler sit flat enough to avoid making a racket rubbing against the bonnet? One reason for the crooked ‘cooler was… broken engine mounts. Yes, the whole engine was off kilter. It’s laughable that it never occurred to anyone to check this most fundamental common problem.

The other reason the intercooler was still leaning, was also the cause for the boost leak. After all the expense and frustration, what was the main culprit? - An incorrectly fitted rubber O Ring. The wrong location of the O Ring didn’t allow the intercooler outlet to sit low enough and be sealed to the top of the throttle body.

Game on!

The following day was the last day before Good Friday, so Karl and Jamie had to work hard to get the ‘Rado running right. They were determined to make sure Matt could spend the Easter long weekend with his father, without having to worry about his ride.

After replacing both broken engine mounts and correctly fitting the O Ring to seal the intercooler to the throttle body, the system was finally airtight and sitting level. Next, the costly Colorado was driven on the dyno to make sure the system was not bleeding boost and working correctly, including the intercooler’s thermo fan operating as it should.

When’s the next fishing trip?

“You guys went over and above. Thank you,” said Matt, who couldn’t be happier with the friendly after-sales support of HPD. Impressed with HPD’s experience and know-how, he was astonished at how basic the causes of his problems were. The Colorado now runs reliably and makes the power it should, so Matt can now refocus on making a living. And finally plan a decent fishing trip.

At HPD we take a huge amount of pride in the high standard of our after-sales support. Even if your story is more unusual than Matt’s, rest assured if you’ve bought a HPD kit and need help, we’ll be there to support you.

Jamie (left) & Karl (centre) worked hard to get Matt's (right) Colorado running right in time for the weekend