New DMG MORI CNC Machine

- 21 Sep 2022

HPD invest heavily in the future of the company. We’re here for the long haul, with programs well underway to achieve HPD’s long term goals for growth and security. The latest investment is the company’s fourth state-of-the-art, five axis CNC machine to further expand HPD’s production capacity.

Arguably the best feature of our new DMG MORI DMC75 monoBLOCK is that it can accommodate 60 different tools, drastically reducing machine setup time.

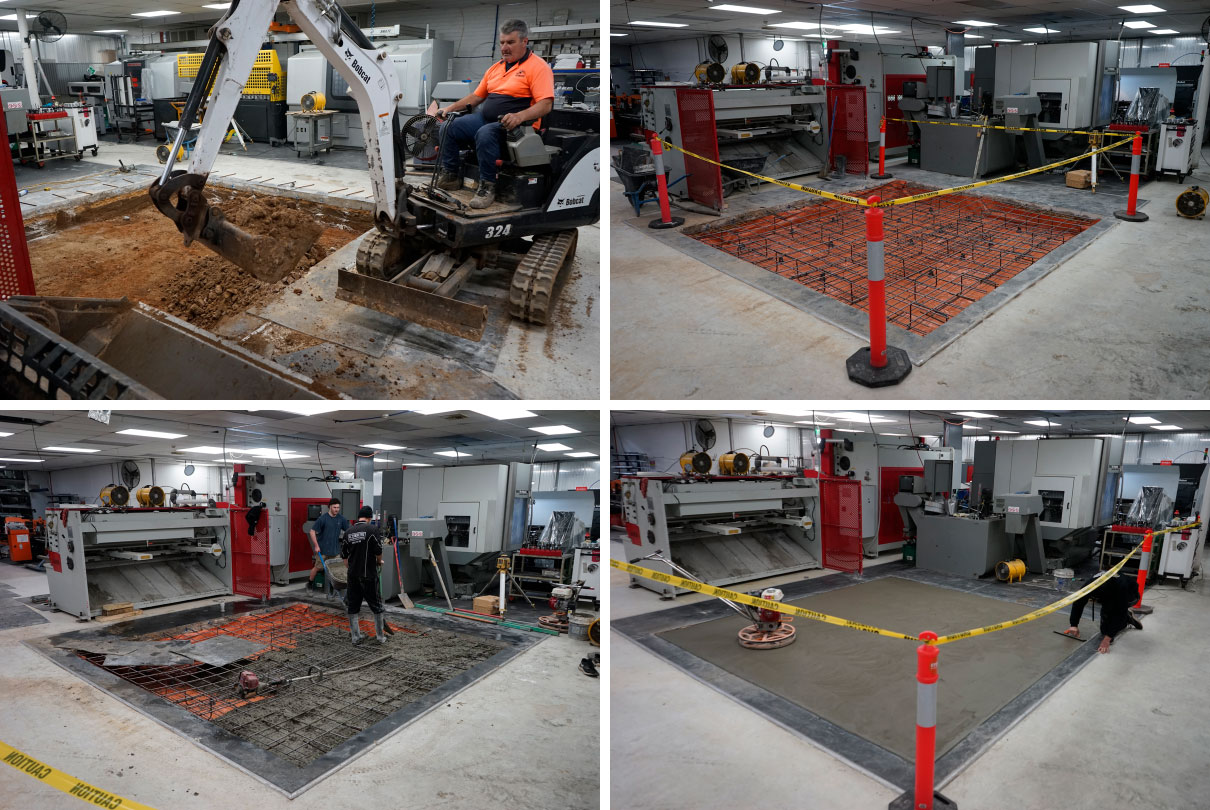

An interesting logistical challenge in accommodating this machine was making sure the production facility’s floor could handle its 12 tonne weight.

To cope with the machine’s substantial weight, a section of the existing concrete floor needed to be removed and the earth underneath dug out in order to enable a deeper concrete foundation to be poured. A month had to be allowed for the concrete to harden.

To deliver this impressive machine, traffic to two intersections needed to be restricted for the enormous new DMG MORI DMC75 monoBLOCK five axis CNC machine to be delivered in sections by two trucks and get unloaded by a crane.

Traffic control was conducted by personnel from Traffic Group Australia who did an outstanding job keeping the busy Edwardstown intersections safe and orderly.

A heavy crane moved each section of the machine that has a combined weight of over 10 tonne. The team from Fleurieu Cranes performed an incredible job moving the extremely complex and expensive machinery. Their vast experience was obvious and reassuring.

As we had calculated, there was (just) enough height for the crane to manoeuvre each section of the machine into the main receiving area of the building.

In the main receiving area, the machine sections were lowered onto trolleys and towed into the manufacturing area.

Assembly and setup procedures are currently underway and will take approximately a week.